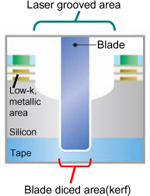

Laser grooving kerf check function

Application processing examples

During blade dicing, when low-k or copper layers are present in the street, which are difficult to cut, usually blade dicing is performed after laser grooving. Adding the kerf check function can optimize this process.

The kerf check can be performed relative to the width or position of the detected groove/kerf. Automatic kerf correction is also possible.

| Conventional kerf check function | The grooved area and the kerf are sometimes misrecognized. |

| Laser grooving kerf check function | The laser groove and kerf are correctly detected and recognized. |

The kerf check can be performed relative to the width or position of the detected groove/kerf. Automatic kerf correction is also possible.

Related Information

Low-k grooving

https://www.disco.co.jp/eg/solution/library/laser/low_k.html

This function can be installed as a user-specified specification.

DISCO offers various kerf check methods for various applications. For details, please contact your DISCO

sales representative.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details