User-specified Processes Using Blade Dicing Saws

Solutions

This is a list of processes that can be performed by installing the user-specified specifications. For more details, please contact DISCO.

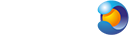

Circle Cut

Circle cut is a processing method that cuts the workpiece into a circular shape by rotating the processing table after cutting with the chopper cut.

This process requires a user-specified software. Please contact DISCO if you are interested in this process.

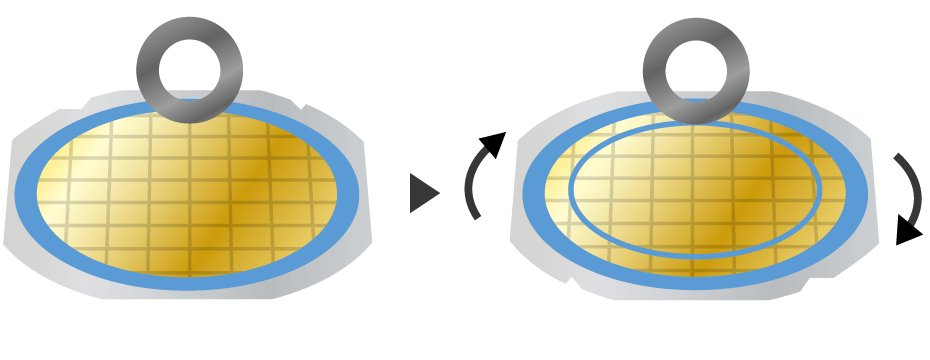

Edge Trimming

Edge trimming is a processing method that creates a height difference by grinding the outer circumference of the wafer using a wide blade. This process is also performed before the grinding process for semiconductor wafers in order to prevent wafer breakage.

This process requires both user-specified hardware and software. Please contact DISCO if you are interested in this process.

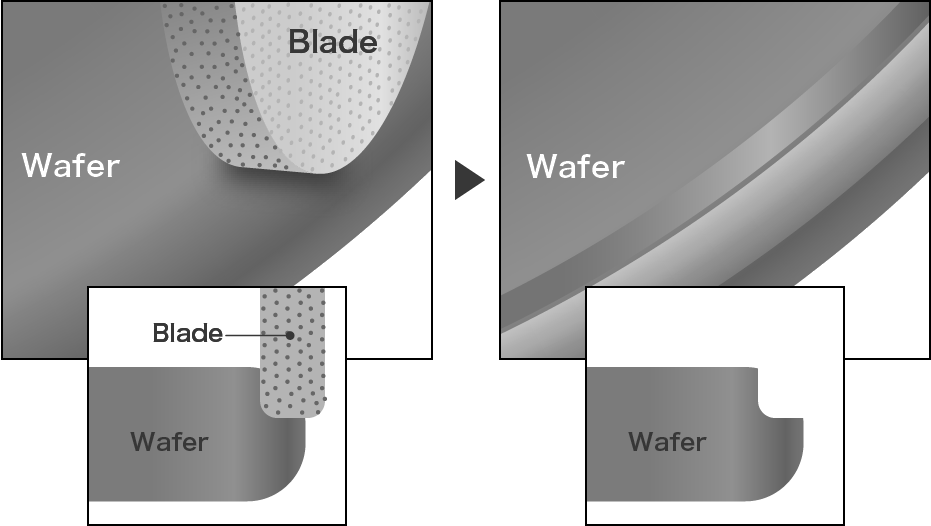

Tilt Process (Inclination Angle Spindle)

The tilt process makes cutting at an angle possible by attaching an inclined spindle to the processing table.

This process is used for processes that require angular cuts, such as processing optical components, etc.

This process requires both user-specified hardware and software. Please contact DISCO if you are interested in this process.

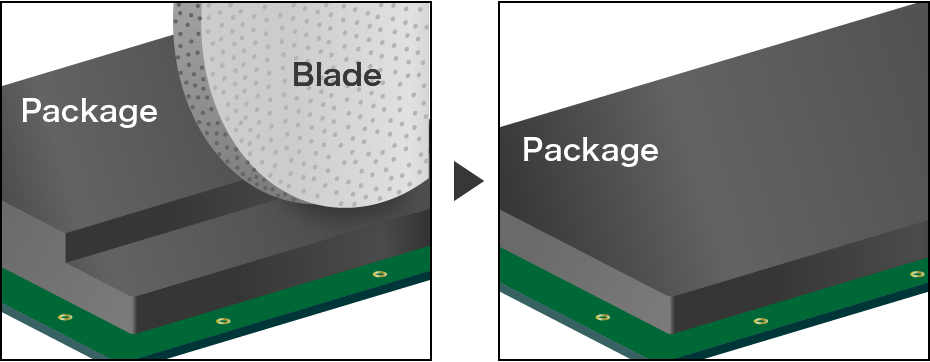

Blade Grinding Process

The blade grinding process is a process used to thin the workpiece by grinding the front surface off of the semiconductor package using a wide blade. With this process, package grinding is possible using existing dicing saws.

This process requires both user-specified hardware and software. Please contact DISCO if you are interested in this process.

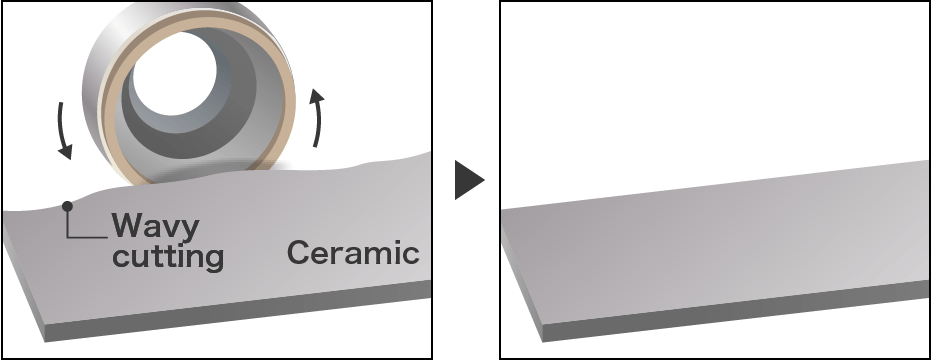

Cup Wheel Process

The cup wheel process is a process that grinds the sidewall of the workpiece by mounting a small cup wheel on a dicing saw that uses a general blade.

This process is used when perpendicularity and straightness of the cross section surface is required.

This process requires both user-specified hardware and software. Please contact DISCO if you are interested in this process.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details